Hui Chuangxin | Changzheng No. 5 B carrier rocket made its first successful flight! Shanghai Power behind "New Arrows Send New Ships"

time2020/05/07

- Hui Chuangxin | Changzheng No. 5 B carrier rocket made its first successful flight! Shanghai Power behind "New Arrows Send New Ships"

Hui

Chuangxin | Changzheng No. 5 B carrier rocket made its first successful flight!

Shanghai Power behind "New Arrows Send New Ships"

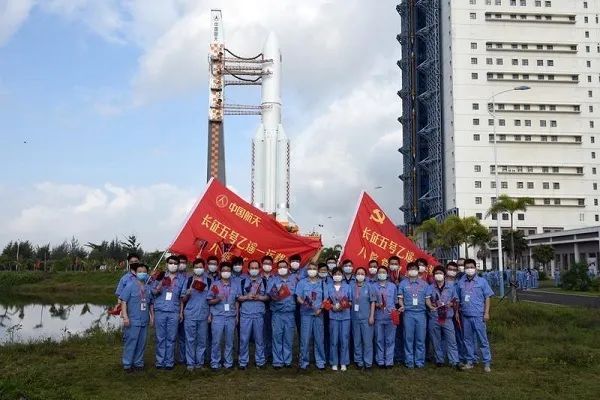

Yesterday (May 5) at 18:00, the brother of

the "Fat Five" rocket-the Long March 5B carrier rocket successfully

launched a new generation of manned spaceship test ship. The Eighth Academy of

China Aerospace Science and Technology Corporation (Shanghai Aerospace

Technology Research Institute) undertook the development work of the four

boosters of Changzheng No. 5 B, as well as safety systems and core-level

supporting batteries, providing 90% of takeoff thrust; Development tasks such

as the energy management system of the spacecraft test ship, solar windsurfing,

measurement and control subsystem of the information management function, etc.

From the unusual weight-loss journey of the

"Fat Five" family to the continuous launch of more than 4 months of

missions, Shanghai Aerospace has selected elite soldiers to overcome

difficulties and contributed "Shanghai Power" to the exploration of

space for a new generation of manned spacecraft .

Shanghai Aerospace selects elite soldiers

to overcome difficulties

Lose more than 700 kilograms to transport

bulky "passengers"

The Long March 5B rocket is as fat as its

"brother" Long March 5, with a core diameter of 5 meters, but it is

about 3 meters shorter, reducing the number of second sub-stages and

inter-stage segments. The bundled 4 boosters successfully "slim" more

than 700 kilograms than the Long March 5.

The head cone of the Long March 5B rocket

booster module looks like a triangular shape from the side, and it looks like a

cute "little penguin" muttering with a small mouth from the front.

The seemingly "little penguin" oblique head cone uses a load-bearing

structure with enhanced strength, but due to its radioactive structure, the

weight of the "little penguin" has always been high, and the

structure accounts for 60% of the weight of the entire nose cone the above.

After analysis by the designer team, there is the greatest weight loss space.

Shanghai Aerospace Long March No. 5

assisted the research and development team to work hard, and finally adopted a

new structure in parallel to support the form, achieving a head and cone

structure weight reduction of about 12%, nearly 150 kg. At the same time,

according to the actual flight of the first five flights of Changwu, the

kerosene tank has a large amount of pressurized gas cylinders. After discussion

and analysis, the designer tapped the potential internally and reduced 1 in

each booster of Changzheng No. 5B. A gas cylinder, at least 23 kg weight loss.

In addition, after eliminating the post-processing pipeline, each booster lost

at least 16 kg. As a result, the four boosters lost a total of more than 700

kilograms.

The "Fat Five" family is a

fashion darling in the aerospace industry. In addition to the bright makeup of

the red paint on the white background, the yellow heat-resistant "soft

skirt" at the bottom not only has a high value, but also has "good

heat resistance and high structural strength". , The structure is soft

enough ". After successful "weight loss", each booster has a

"height" of 27.7 meters, a "waist circumference" of 3.35

meters, and a net weight of 14.3 tons. They provide the main support for the

Long March 5B rocket.

The "Fat Five" family is very

dazzling in makeup with red paint on white background, and is the fashion

darling of the aerospace industry

Six years of research and development of

tail wing "body"

The structure of Changzheng No. 5 B large

tail wing is currently the most complicated structure tail wing in China, and

its technical indicators bear many national firsts.

The large tail is huge and simple from the

outside, but the increase in area, volume and weight is not a simple

enlargement for the process. Many process parameters need to be explored. The

development process involves machining, sheet metal, riveting, welding, surface

treatment, and heat treatment , Adhesive bonding and other process types, the

process is complex.

The production process of the four-piece

tail wing took less than 4 months, but before that, Shanghai Aerospace ’s tail

wing development and production team has been fully prepared for 6 years.

Technicians have successively carried out a number of technological

breakthroughs and technological tests, such as large thickness and high

strength rivet riveting test and other technological test work, which solves

the technical difficulties in the production of key and important parts,

special process control of bonding and measurement and detection methods

Subsequent development laid a solid foundation.

The empennage frame and the empennage

high-temperature curing mold tire are the most important technological

equipment for the production of the large empennage. After four years, the

tooling design team of the team tracked the entire tire production, grasped the

production progress of the tire and the details of each production process, and

finally accepted it smoothly.

"New Ship" Energy Management is

Safer and Newer

The new-generation manned spaceship

experimental ship energy management system is currently the only

"double-insurance" power system in China. "In the case of a

complete failure of the main power supply, the auxiliary power supply can

complete the task independently. This is equivalent to two sets of power

systems, one set of main power supply, and one set of auxiliary power supply,

which can complete the task independently, which is equivalent to double

insurance. "The new generation manned spaceship experimental ship energy

management system chief designer Zhong Danhua said that the main power supply

itself has three units with three independent controllers and battery packs. If

any unit fails, the remaining two units can also be independent. Complete the

flight mission.

As a PLUS version of the Shenzhou

spacecraft, the 6-seater new-generation manned spaceship experimental ship is

twice the configuration of the 3-seater Shenzhou spacecraft. The new cabin

structure design has brought a lot to the docking of the solar cell wings and

the cabin Big difficulty. After many researches and experiments, the research

team determined that the solution of "air floatation platform + metal

extension plate" will be adopted for the first time on the manned

spaceflight model.

The new spacecraft test ship team has been

stationed in the Hainan Wenchang space launch site since early January. Since

the first flight of the Long March 5B was the first tough battle this year, and

the new crown pneumonia epidemic raged, every test team at the launch site

fought all out. At the same time, we will strengthen our conviction, face the

difficulties, and win major projects.

Source: Xinmin Evening News